5 Common Supply Chain Issues and How To Overcome Them

The pandemic threw the world for a loop in more ways than one. However, it did present a chance for some business owners—mostly those specializing in e-commerce—to flourish. But many thriving businesses hit a brick wall due to a severely disrupted supply chain. Recognizing these five common supply chain issues and how to overcome them gives businesses the best chance of achieving ongoing success.

1) Meeting Customers’ Demands

Before consumers make a purchase, they should know what to expect regarding pricing, obtainability, and delivery timelines. Sadly, it can be difficult to meet or exceed customers’ demands because of the volatile nature of the supply chain.

Companies who want to broaden their selection of suppliers can do so via a method known as supply chain diversification. Having many sources can lessen the likelihood of shortages and prolonged delivery periods that might otherwise stem from a single supplier’s failure to satisfy demand. Despite the unknowns, you can maintain your commitment to excellent customer service.

2) Managing Inventory

Because of the scarcity of supplies due to an inconsistent supply chain, the demand for things could skyrocket. This increase can be a real problem for companies if they don’t have the means to keep up. This is particularly true for those offering electronic devices and appliances, but virtually any sector can face this challenge.

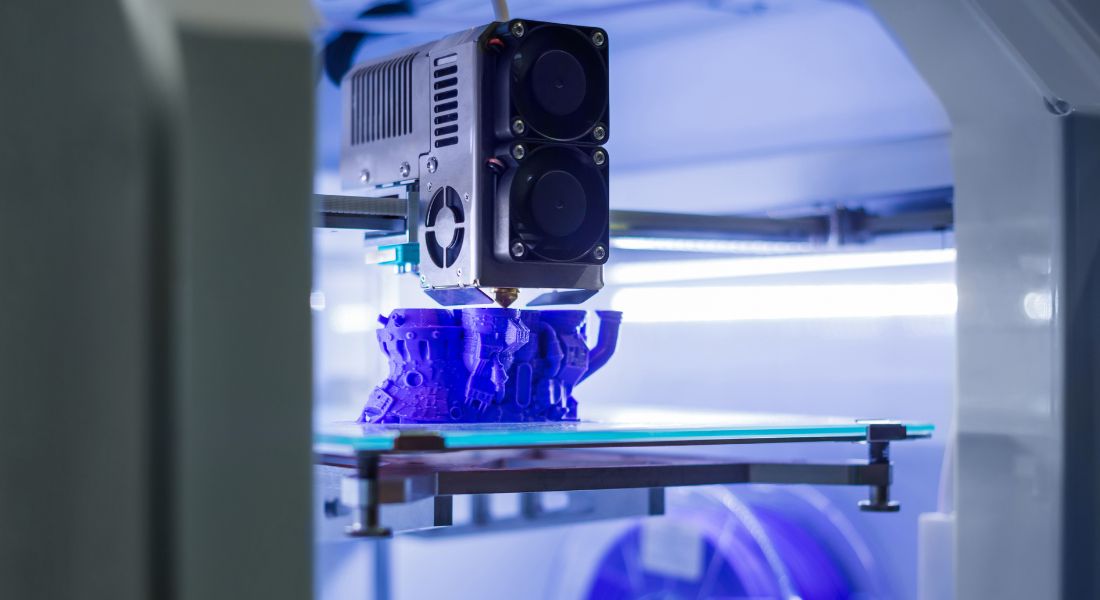

Businesses must either adopt or enhance techniques for demand forecasting. You might check the most important items on the list using your order management software. Place larger orders for these best-selling items to maintain stock levels amid ongoing supply chain instability if possible. There are hacks you can use to handle the fluctuations and improve the economy, such as relying on 3D printing to produce some items.

3) Going Back on Your Word

Overpromising and underdelivering is an error that may be no fault of your own. However, you must avoid these detrimental mistakes. Robust inventory management skills are essential to minimize overselling, especially during peak shipping seasons such as the holidays.

Try setting a standard stock level with each product, particularly with those that have historically performed well, to determine the bare minimum of inventory you need always have on hand. This measure can help you anticipate restocking demands and provide breathing space if an item suddenly becomes unavailable.

4) Lack of Doomsday Preparation

It’s much easier to anticipate rather than react in the business world. Companies across all sectors must have a can-do attitude to succeed in the face of production and supplier delays. An overwhelming number of businesses of all sizes crumbled during the pandemic because they failed to make a plan. You shouldn’t necessarily have stock going up to the rafters, but a keeping a “Plan B” is imperative.

5) Too Much To Overcome

Adapting to the new normal of facing unanticipated problems takes resiliency. Amid another worldwide disaster, businesses may see unanticipated spikes in demand and interruptions in their supply chains. Rather than seeing this as a problem, you should see it as an opportunity for unprecedented success. Thoroughly develop and execute a plan to deal with these challenges, whether that involves reaching out to numerous vendors or ramping up internal processes. After all, luck is when determination meets opportunity, so go and make your luck!

Understanding these five common supply chain issues and how to overcome them can help small businesses and e-commerce shops survive this murky time. Adapting to these challenges is more vital than ever before.